Our Story

Donkey & Goat is celebrated for being amongst a handful of pioneers in the Natural Wine community because in 2004 they were unique for their ecological principles driving decisions in both the vineyard and the cellar and ten years later for promoting transparency, being one of the first to list ingredients on their label. Founding winemakers Jared Brandt & Tracey Rogers spent a year with the inimitable Eric Texier in 2002 studying the art of crafting natural wines in the Rhone Valley before co-founding Donkey & Goat in 2004 in San Francisco.

Sept. 2002, Cleaning bins in France

First Berkeley Winery, 2006- 2011

Original Label By Jane Fisher & Colin Frangos

Second Label, 2008-2014

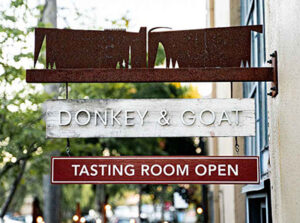

In 2006, with distribution around the US and a growing mailing list, Donkey & Goat moved to 2323-B 4th Street in Berkeley where they built out the first winery facility that is now home to Maître de Chai Wine. Five years later in March of 2011, with a newborn Lily Brandt, the Brandts embarked upon the extensive build out for the current Winery & Tasting Room at 1340 5th Street which opened in July of 2011. Today the Berkeley Wine Block includes three additional wineries that the Brandts helped bring to the block: Broc Cellars (2013), Hammerling Wines (2018) and Vinca Minor (2019).

The Making of 2022 Vintage

Connor Bockman, Director of Winemaking

Zachary Becerra, Former ’22 Harvest crew & Current Director of Hospitality

Harvest Interns Tony & Hanna crushing Cab Pfeffer

27,460 pounds of Pinot Gris & Cab Pfeffer packed in our office after the Week in the Trenches

Iconic California Pét Nat

In 2009 Jared began experimenting with sparkling wine after sharing a bottle of French Pétillant Naturel (PÉT NAT for short) with another inimitable winemaker in Los Angeles. In 2011 we debuted our first vintage of Lily’s Pet Nat, Sparkling Chardonnay that is still made today!

“I was inspired to make Pét Nats by both the traditional Pétillant Naturel made by vignerons in rural France for their own consumption and the desire to make bubbles without any additives.”

— Jared Brandt

Founding Winemaker & Co-owner

Donkey & Goat First Vintages

2011 Lily’s Pet Nat, Anderson Valley

2013 Kraisey Pet Nat, Anderson Valley

2015 Ramato Pet Nat, Anderson Valley

2015 Clairette Pet Nat, El Dorado

2016 Blanca Pet Nat, Anderson Valley

2017 Pinot Meunier Pet Nat, Russian River

2021 Gruner Pet Nat, California

2021 Merlot Pet Nat, Mendocino

California Orange Wine Pioneers

In 2007 we dabbled with skin contact Roussanne bottled as Tamarindo and by 2009 were labeling a 14 day skin contact Roussanne as Stone Crusher which is still made today!

Donkey & Goat First Vintages

2009 Stone Crusher, Roussanne, El Dorado

2012 Grenache Blanc, El Dorado

2014 Ramato Pinot Gris, Anderson Valley

2016 Sauvignon Blanc, Mendocino Ridge

2017 Alveare, Marsanne, El Dorado

2018 Stems & Skins Vermentino, El Dorado

Farming Microbes

We work with a handful of farmers who share our ethos and drive to make delicious terroir-driven wine while considering the larger environment, planet, and our impact. We like to grow with a farmer rather than grow our list of farmers.

We currently make wine from the following California AVA’s and since 2021 we also blend these celebrated AVA’s to make Climate-Driven Creative Wines out of necessity.

Our celebrated AVA’s:

- Anderson Valley

- El Dorado

- Napa

- San Benito

- Sonoma Mountain

- Russian River

- Rutherford

- Mendocino

Ron Mansfield, Goldbud Farms

El Dorado Farming with Goldbud Farms

“It took Jared two years to convince Ron to trust his Fenaughty Vineyard Syrah in our hands and we made our first vintage in 2005. That was the start of our longest grower relationship. Ron and Chuck Mansfield are salt of the earth, meticulous, passionate farmers who always think about the resulting wines with every decision they make.”

–Tracey Rogers Brandt

The Gilman Wine Block

Berkeley has long been in the epicenter for the farm to table movement thanks to the legendary Alice Waters. Today Berkeley also claims an extraordinary concentration of natural winemakers with Donkey & Goat, Hammerling, Broc Cellars and Vinca Minor Wines all in the Gilman Wine Block where we operate our Tasting Rooms, hold block parties and more.

Join Our Community

Get 10% off your first online order when you join our mailing list!